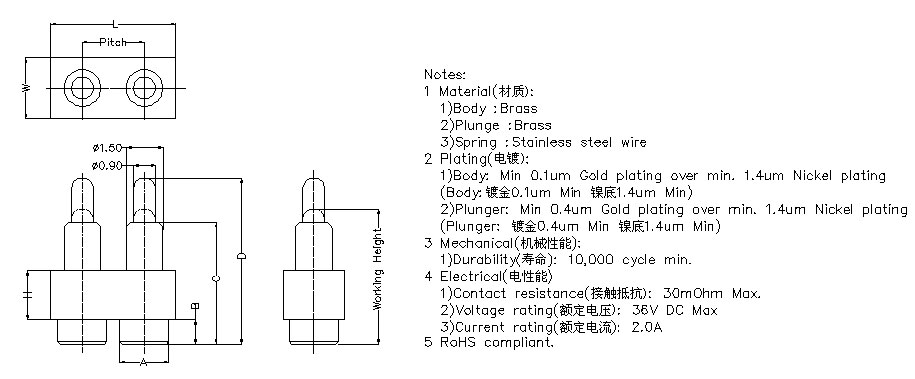

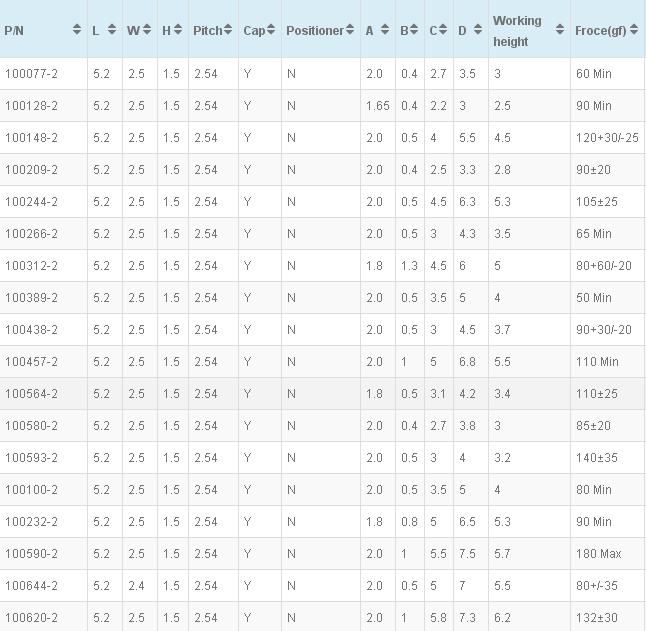

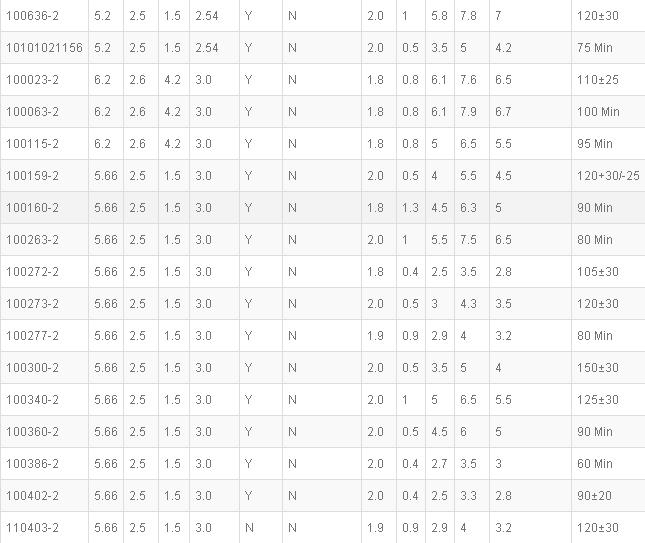

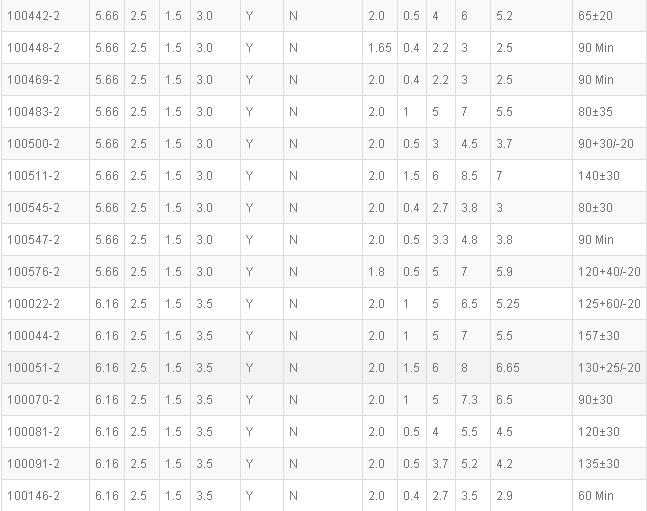

2 pin pogo pin connector plain base type

Housing: PPA, PA46, PA9T, LCP

Pogo Pin OEM

PACK:

Bulk: aluminum foil bag.

Reel: diameter Φ330mm; carrier tape width: 12, 16, 24, 32, 44mm.

=================================================================================

product testing introduction

| Electrical performance |

| 1 |

Contact impedance |

30 mohm Max at working stroke |

Top-Link factory testing standard* |

| 2 |

Insulation Resistance |

500 Mohm Min |

EIA-364-21 |

| 3 |

Dielectric Withstanding Voltage |

No flash-over,air discharge,breakdown or leakage |

EIA-364-20 |

| 4 |

Temperature Rise vs Current Rating |

30 °C Max.

temperature rise at specified current |

EIA-364-70 |

| Mechanical performance |

| 1 |

Spring force |

refer to product drawing |

EIA-364-04 |

| 2 |

Retention Force |

0.5Kgf(4.5N)Min. |

EIA-364-29 |

| 3 |

Durability |

10,000 cycles Min.

No physical damage Resistance after test 30 mohm Max. |

EIA-364-09 |

| 4 |

Vibration |

No physical damage,No electrical discontinuity more than 1i second. |

EIA-364-28 |

| 5 |

Mechanical Shock |

No physical damage,No electrical discontinuity more than 1i second. |

EIA-364-27 method A |

| Environmental |

| 1 |

Solderability |

solder coverage area Min.95% |

EIA-364-52 |

| 2 |

Salt Spray Corrosion |

No physical damage. Resistance after test 100 mohm Max. |

EIA-364-26 condition B |

| 3 |

Resistance to Solder heat(IR/convection) |

No cracks,chips,melting,orblister |

EIA-364-56 |

| 4 |

Humidity |

No physical damage, Resistance after test 100 mohm Max. |

EIA-364-31,method ii,condition A |

| 5 |

Thermal Shock |

No physical damage, Resistance after test 100 mohm Max. |

EIA-364-32,method ii |

| 6 |

Temperature Life |

No physical damage, Resistance after test 100 mohm Max. |

EIA-364-17,condition A,condition 4 |

| Environmental |

| 1 |

peel force |

10-130 gf |

EIA-481 |

| 2 |

Drop Test |

|

Refer to drop test Standard of Molex |

- Remark: Considering the difference between test spot and actual work spot, the impedance test condition defined by Top-Link is based on the whole working stroke. This is what we generally said dynamic impedance testing, it differs from the static test condition of ELA-364923, the durability test standard is also based on this test condition.

- -----------------------------------------------------------------------------------------------------------------------------------------------------------

- KLS is equipped with comprehensive inspection and reliability testing equipment.

- KLS attaches great importance to quality management of each link, including IQC, IPQC, 100% dynamic testing of spring force and contact impedance , 100% appearance inspection, FQC sampling inspection, CQC, design verification, regular reliability testing, failure analysis, and so on.

- KLS has implemented strict and effective quality control over each link which includes product design, sample preparation, trial production and mass production. As a consequence, our product quality is guaranteed.

- ==========================================================================================

- pogo pin connector OEM type

1, small diameter, fine type products

The minimum can be done is below 0.75

2, high durability

Maximum durability of up to 1 million times

3, large current

Maximum up to 15A current

4, high reliability

100% dynamic impedance testing to ensure 100% functional zero defects

5, lower operating height

Minimum working height of up to 1.5mm, the chopping block can be lower

6, high precision (size & forward force)

Height tolerances up to +, - 0.05mm positive up to + / - 10%

7, non-standard structure

Customer requirements can be customized according to customer requirements, such as: mushroom head structure

|